Pydhonie, Mumbai, Maharashtra

- GST NO. : 27AABFH7990R1ZG

View Mobile Number

Shielding Products

Leading Manufacturers, Exporters, Wholesaler, Retailer of Lead Glass, Lead Lined Doors, Lead Lined Partition and X- Ray Lead Sheet from Mumbai.

| Business Type | Exporter, Supplier, Retailer, Trader, Importer |

| Thickness | 10mm |

| Material | Lead Glass |

| Shape | AS Required By Cleint |

| Application | Radiation Shielding |

| Size | 1200x800 Mm, Customized |

| Type | Lead Glass |

| Appearance | Trasparence |

| Structure | Glass |

| Lead Content | 55% to 65% Pb |

| Lead Equiv.(mm) nominal | Min 2mm Pb equiv |

| Thickness Tolerance (in) | +0.50 |

| Standard Edgework | Seamed always |

| Higher Lead Shielding | Available upon request |

| Payment Terms | Other |

| Delivery Time | Immediate |

| Packaging Details | Lead Glass is packed in Wooden Box with all side thermocol inside for stiff packing. |

Lead Glass also referred to as Radiation Shielding Glass or X-ray Glass is suitable for installation in Screens, Windows, Walls, And Doors. Lead Glass allows technicians to view the imaging or radiation therapy procedures.

We have lead glass in a variety of standard sizes and also offer custom size lead glass up to a maximum of 1200mm x 2400mm. We have ready stock of lead glass for most dimension for quick delivery.

HMS Metal Corporation is a major provider of x-ray glass and radiation protective lead glass shielding products worldwide.

Xray glass and radiation protective lead glass is utilized when a clear view and radiation shielding is of absolute priority in diagnostic, therapy, isotopic, or nuclear radiation sources. X-ray glass is used for radiation shielding in medical treatment, imaging, testing, inspection, experimentation or energy production.

General Information and Options for X Ray Glass

- Available in 1.8mm, 2.0mm, 2.4mm, 3.2mm and 3.7mm lead shielding equivalences. Higher ratings are available upon request.

- The highest density x-ray lead glass available for the most efficient medical radiation shielding quality, and yet also allowing approx. 88% Spectral Light Transmission

- Uniformly dense and is a composition of high quality materials providing a dependable shielding value.

- Utilized for medical x-ray, gamma, alpha and beta photon shielding only.

- Not for thermal neutron or fast neutron shielding. X-ray lead glass will NOT shield against Magnetic Resonance Imaging (MRI), electro-magnetism or radio-frequency, ultrasound, laser or any non-ionizing types of radiation.

Applications

- Uses of X-Ray Glass in Medical Diagnostic X-Ray Imaging Shielding : Standard X-Ray Protective Lead Glass is typically utilized in medical diagnostic imaging control windows for applications of 150kvp x-ray gamma radiation energies or less such as in radiology, fluoroscopy, angiography, cardiac catheterization labs, computerized tomography (CT scan), chiropractic x-ray and mammography rooms. X ray lead glass is not for use in MRI applications

- Uses of X Ray Glass in High Energy Radiation Therapy Oncology Shielding : For higher shielding equivalency x-ray protective lead glass for utilization in high energy gamma radiation shielding applications of 511kvp such as imaging control windows for Positron Emission Tomography Rooms (PET Scanners) or in Medical Radiation Therapy/Oncology Cancer Treatment facility rooms such as Gamma Knife, Simulator rooms, Brachytherapy, Dose Calibration, Hot Labs, or High Dose Radiation (HDR Rooms).

- Uses of X-Ray Glass in Industrial X-Ray NDT Shielding : Specialized lead windows for industrial applications in non-destructive testing (NDT Rooms) or for certain nuclear or high energy isotopic shielding of hot cells or glove boxes. All radiation shielding requirements for x-ray lead glass control windows in any medical or industrial application or use must always be determined by the customer’s or end user’s qualified health radiation physicist, radiation expert or radiation safety professional.

Storage

Lead Glass is fragile material thus on arrival of Lead Glass it must kept in place where least movement is required. Also it should be kept away from places of on-going construction work area.

Handling

Lead Glass being highly fragile material, thus handling of lead glass must be done with extreme care. Use of Glass handling tools should be used for handling and storage.

Featues :

- High quality optical grade lead barium type X-Ray lead glass

- Contains over 60% heavy metal oxide, including at least 55% PbO

- Surfaces are mirror polished

- Excellent for use in medical facilities, laboratories, airports, and screens for radiation

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Power coated |

| Usage/Application | X ray room, Radiation proof rooms, Hospitals |

| Features | 2 mm lead sheet sandwitched in between door frame as well as in door leaf Design: Customized |

| Design/Pattern | Customized |

At HMS Metal Corporation, Our Radiation Shielding Lead Lined Wood Doors are made-to-order according to your Size & Specifications. We take great pride in our quality and quick lead time. . The door size, veneer type, and lead thickness are per your project requirements. We will provide options for your entire door mounting hardware, door operation hardware as well as any leaded glass and lead lined glass frames.

Our lead-lined doors are revolutionary departure from traditional carpentry nailed door to modular factory press doors.The lead sheet extends the full height and width of the door with single un-pierced lead sheet. Our lead-lined doors and frames achieve effective radiation protection.

Modular Innovation applied to your Radiation room.

- Our Radiation Shielding doors offer an unparalled advancement by eliminating traditionally problematic nailing on doors thus provides necessary attenuation levels of shielding. Our Radiation Shielding door includes everything needed for quick and cost efficient installation.

- An extensive range of materials and finishes are available to provide maximum design versatility while meeting the aesthetic and performance needs of any facility.

Shielding Information

- HMS Metal offers a variety of lead thickness. The lead thickness is determined by the intended application of the product and the determination of thickness is the responsibility of the purchaser. For frames and doors the lead sheet is applied to the inside of the skin of the door on the “pull” side. Ensuring the continuity of the lead lining in the frame and the wall is the responsibility of the frame installer.

- Our lead shielding is of a continuous sheet of lead as specified. The sheet lead will be unpierced, free of defects, laminations, scale blisters, cracks or penetration. The amount of shielding necessary in a door or frame should be equal to the shielding required in the wall in which it is to be installed in. The sheet lead shall be shaped to fit into the frame contour and inserted in the frame. All lead joints are welded together to insure continuity of shielding and to secure in place during transit and installation.

Hardware & Shielding

Hardware selection can be the toughest decision on the success of your installation process. The final hinge system has to be appropriately specified to handle the heavy weights that the sheet lead imposes on the door. Door hardware is usually specified and supplied by others. Hardware selection should ensure lead lining in its components are equal to the door and frame assembly. Necessary precautions are needed in the field when installing the hardware to prevent penetration of existing lead shielding in door and frame.

Site Storage and Protestion of Material

All materials must be thoroughly inspected upon receipt of goods. All discrepancies and/or damages shall be immediately noted and reported in writing to us and on the freight bill of lading when received. All materials received shall be properly stored on blocks or skids with adequate clearance from floor with a covering that will allow adequate circulation around product. Keep materials free from any contact of water, moisture, or dampness on a flat, dry level surface. The room should be properly ventilated to carry the dampness out of room. Also avoid any exposure to direct sunlight, extreme heat source, and humidity or excessive temperatures.

Doors Installation

- Do not start your installation in areas that still contain excessive moisture from wet plaster, or cement.

- Ventilation systems should be operational and functioning correctly.

- Allow doors to acclimatize to surroundings before actual installation.

During installation the frame should bet set plumb, square and level at the correct elevation. Ensure that the frame is adequately secured into the studded wall to properly support the door weight and size. Use a proper hinge system rated for door weight and size. We recommends the use of pivot or continuous type hinges for all applications. When butt hinges are to be specified and used they must be fully rated for the weight and size of the lead lined door. A minimum of three hinges should be used for doors up to 90″ in height. For every extra 30″ of door height add one more hinge or portion thereof. Be sure to follow all manufacturers’ recommendations and guidelines for locations and quantities, when different to above. Consult with the site physicist to insure proper shielding is maintained at each opening.

Frame Installation

It is critical that the frame be installed by an experienced person who can ensure it to be plumb and square in the available opening that is provided. The frame must be securely fastened into place within the studded wall prior to the receiving of the drywall. The lead lined wall must then be built into the frame to effectively provide a shielding overlap for the lead in the face and throat of the frame.

Order Information Required

When ordering a door and frame it is critical that all necessary information be supplied. We cannot be held responsible for insufficient or missing information. It is up to the purchaser to ensure that all necessary information is provided at time of quoting. When ordering frames for lead glass, please specify whether the width and height you provide are for the glass viewing area or the frame. E.g.: When specifying 12″ x 12″ the actual glass could be this size but not the viewing area. The frame can add a few inches all around and the glass sits inside of this frame. The 12″ x12″ can be taken as an inside frame size but is usually considered an outside frame size. A small sketch is usually the best clarification in ensuring there are no mistakes made.

Considerations and Information Required When Oedering :

- Door Size: Exact width and height

- Door Swing: See swing selector page

- Lead Shielding: Thickness or lead glass lead equivalency

- Door Frame Type: Hollow Metal – welded or knock down type Window Frame – Welded or Split- type

- Door Type: Metal Face or Wood – Type of finish (veneer, birch, oak, plastic, laminate etc.)

- Throat of Frame

- Wall thickness and construction: Wood stud, metal stud, masonry

- Type of Hardware required:

- Door Closer

- Hinges and number – pivot, butt, continuous (Hinge capacity must be verified for compatibility with door weight)

- Passage Set – Lock set or latch

- Labeled? (Fire rating)

- View Window (Size, type and location)

- If ordering double doors specify which leaf is to receive astragal

- Any options, locations or pertinent information relevant to the ordering

- Brand, manufacturer preference

Note: It is necessary when supplying your own hardware to provide all the pertinent information on what you’re using so we can ensure our door and frame prepping match your hardware requirements.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Lead Lined Doors |

| Material | High Tensile Lead |

| Application | Clinical Use, Hospital Use, Nursing Homes |

| Finishing | Polished |

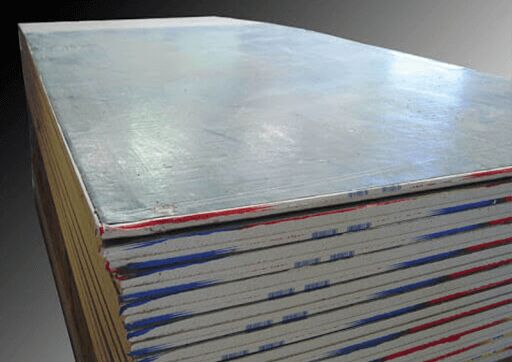

Structural Radiation Shielding we offer lead backed plasterboards or plywood and complete range of X-ray Room or Imaging Room shielding products and installation services.

Wall, Ceiling and Floor Panels – X-ray protective lead lined panels and partitions and lead bricks.

Door Sets – X-ray protective lead lined door sets, including Hinged Wooden Doors and Door Hardware.

Observation Windows – X-ray protective observation windows, including Lead Glass.

Screens – X-ray protective screens, including mobile screens and movable shield.

Room Construction – Lead Lined Partition Room with support of plywood or gypsum is constructed. We have successfully completed Lead Partition Room in Nair Dental College where we have used plywood for lead support.

HMS Metal specializes in lead shielding products for government, commercial, industrial and medical applications.

HMS Metal provides unprecedented support for architects, designers, contractors or private customers to help facilitate the correct lead shielding needed for your specific application.

This requires protective barriers within walls, floors, ceilings, entrance doors, windows and for the staff working in a diagnostic x-ray room.

Advantages of installing plywood/gypsum board with lead lining

- Provides effective floor-to-ceiling radiation protection

- Offers design flexibility for use in walls, floors, and ceilings

- Eliminates the risk of radiation leakage when properly installed

- Available in varying thicknesses to meet a wide range of shielding requirements

Cutouts & Penetrationd

- When installing lead lined plywood or drywall (lead lined sheetrock, lead lined gypsum), all cut outs, seams and penetrations will require sheet lead or lead plate to ensure continuous shielding throughout the room. Proper installation of additional lead wherever penetrations are created will eliminate potential leaks and ensure total protection.

- Additional sheet lead can be supplied to easily allow for the proper shielding of penetrations such as receptacles, light switches, ducts and telephone/data cables.

Providing Suffcient shielding from Different types of Radiation

- Different types of radiation are emitted with different levels of energy behind them, but all are caused by unstable atoms. The greater the energy of the radiation, the greater the level of shielding required to safely shield against it. When proper shielding is not provided, radiation can cause burns on the skin and at high levels, puts people at risk of radiation sickness.

- Alpha radiation (α) is comprised of very weak particles that are unable to travel more than a few centimeters when airborne and therefore requires little shielding. In fact, the outermost layer of human skin is actually enough to protect against this type of radiation.

- Beta radiation (β) particles can travel farther because of its small mass and requires more protection, such as heavy clothing or a thick piece of plastic, wood or aluminum. Certain beta radiation particles can penetrate and burn the skin.

- Gamma radiation (γ) consists of photon energy, not particles, and can travel far distances. Protection from gamma radiation requires the use of dense materials such as lead to provide effective radiation shielding. Gamma rays are biologically hazardous and can cause tissue, bone and organ damage if proper protection is not used during long periods of exposure.

- X-ray radiation are considerably stronger and have a longer wavelength than other types of radiation and requires thick, dense shielding, such as lead. Because prolonged x-ray radiation exposure can cause DNA mutations, it is classified as a carcinogen.

Impotant fator of determining Your Radiation Shielding Requirement

- Radiation shielding is available in varying degrees ranging from protective vests and leaded glass barriers to rooms constructed with lead lined drywall, doors and windows. High energy radiation applications and those involving nuclear power may also require the use of lead bricks for additional shielding protection.

- There are various lead shielding considerations including radiation type, equipment orientation, workload and occupancy but exposure time and distance are the most important in calculating the level of protection required for your application.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Type | Lead Sheet |

| Material | Foam |

| Thickness | 0.5-10mm |

| Color | Black, Grey |

| Port | Nhava Sheva, Mumbai |

| Payment Terms | T/T |

| Delivery Time | Depending on Quantity |

| Packaging Details | Safe Packing |

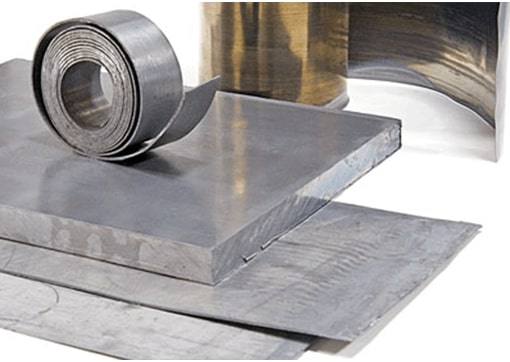

We are the GLOBAL LEADER in MANUFACTURING LEAD SHEETWith purity of 99.5% and higher, our Lead Sheet is the best material of choice in any design for X-Ray or gamma ray shielding.

Its high malleability, density and consistency offer easy shaping of the material, and also provide maximum protection with minimum thickness to suit your application.

We provide X-Ray shielding lead in a variety of thicknesses and sizes, in various widths and lengths.

Capabilities include custom fabrication of X-Ray Shielding Lead to unique customer specifications, tolerances and requirements. Along with custom X-Ray Shielding capabilities.

Characteristics X-Ray Leadsheet

Some characteristics of our sheet lead that make it the most commonly used lead radiation shielding material for many applications:

- Density: Lead sheeting provides better shielding against radiation compared to a thicker layer of plaster, glass or concrete. Its limpness also offers superb soundproofing capabilities.

- Malleability: Lead is highly malleable and can be easily shaped to match the client’s radiation shielding specifications. We can build it into, or add it to walls, doors, and window frames for effective radiation protection.

- Usability: Lead sheet are easy to unroll, bend, cut, and shape without the need of special tools.

Key Benefit

- Lead Sheet is produced in our own factory by our skilled technicians.

- We produce Rolled Sheet lead from just 0.5mm thk to 50mm thick.

- Produced from refined pure lead & variety of special alloys upon Request, conforms in

- accordance to ASTM B-29, B-749 and Federal QQ-L-201F, QQ-L-171E.

- Standard lead sheet size in width of 3ft/4ft/1mtr or any size of cut pieces available.

- Installed correctly, lead sheet poses no risk to the environment and people.

Application in Radiation Shielding

- Lead sheet is commonly used to shield healthcare workers from radiation.

- For instance, in <b>Radiology Rooms / Cath Labs / X-ray & Imaging Rooms / Dental OPG X-ray Rooms.</b>

- Lead Lined Wall / Doors / Frames / Partition / Panels </b>create a barrier between the x-ray machine and the x-ray technician for protection against radiation.

Packing

- Each roll of Lead Sheet is wrapped with HDPE Plastic sheet to avoid any kind of transit damages. Further our Product Colour Code labeling and marking helps your warehouse keeper/production floor people easily label out the required size.

- Our export worthy packing makes sure that our product reaches you safely and without any damages in transit.

Storage

- Lead is one of the heaviest metals in use in the modern world. Care must be taken to ensure that if lead sheet is stored above ground level, the means of storage is strong enough to accept the weight of the product.

- Irrespective of the method of storage, lead sheet must be kept in a dry environment until the application phase to ensure that no unsightly staining can occur if the storage area is damp.

- Surface of Lead Sheet can be scored or damaged if it comes into contact with rough surfaces or sharp objects.

Handling

- Lead is a soft heavy metal this brings advantages during application but caution must be exercised in handling. Lift with Proper lifting equipment - seek assistance where necessary.

- Lead is a soft heavy metal this brings advantages during application but caution must be exercised in handling. Lift with Proper lifting equipment - seek assistance where necessary.

- PERSONAL PROTECTIVE EQUIPMENT (PPE) to be used while handling lead . Eye/Face Protection: Wear safety goggles. Skin Protection: Wear protective clothing e.g. gloves, aprons, boots. General Hygiene Considerations while handling Lead. It is good practice to: avoid breathing product avoid skin and eye contact and wash hands after handling.

Health & Safety

- Wear the appropriate protective clothing & gloves when handling Lead.

- Wash your hands and forearms as soon as you finish and before you eat or drink.

- For health and safety reasons it is recommend there be no exposed lead after your installation is completed. Disposal of all scrap lead must be handled in a proper environmentally & responsible manner. Check with your local by-laws for the proper way of disposing of the remaining scrap lead material. Installation should comply with requirements of local regulatory agencies and standards specified.